The three major kinds of foam used in mattresses are polyurethane foam, visco-elastic memory foam, and latex foam. Each kind of foam has variations. First, there are different ingredients in these foams. Then there are different densities and firmness levels. Now gel is infused into different foams to add desired characteristics.

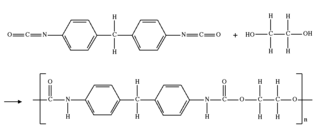

Polyurethane (PU) foam is made by linking large molecules, usually isocyanates, to each other with modified oil molecules called polyols, usually petroleum-derived. Polyurethane foam is very durable and supportive.

Most of the issues with polyurethane foam are related to its manufacture. Isocyanates are toxic before becoming part of the PU foam. I used to work on a line making foam-filled panels for garage doors. Two liquids were injected between the sheet metal skins of the doors. They immediate blended and swelled into foam, which cured to become firm. One of the liquids was an isocyanate, and we had to be extremely cautious around it.

Another issue is outgassing. For some time after it is made, polyurethane releases gasses with an unpleasant odor. Careful selection of ingredients reduces the outgassing and the odor.

Many mattress manufacturers use “plant-based” polyurethane foam. From 15% to 20% of the polyols in this foam are from plant-derived oils. At the current level of technology. No more plant oils can be used and still have a high quality polyurethane. With further research & development, this may change. The plant-based polyols used are most often from soy oil, but other hydrocarbons, such as coconut oil and palm oil, are sometimes used. Further technological development may see the use of many other plant oils.

As stated above, memory foam was developed from polyurethane. It is denser than polyurethane. Visco-elastic foam also is more sensitive to heat. When someone sits or lies on it, the memory foam becomes softer, allowing the person to sink into it. This way it conforms to a sitter’s or sleeper’s body contours. The memory foam can be formulated to be more or less heat sensitive, therefore more or less conforming. With memory foam beds now widely available, manufacturers are competing to make the best memory foam mattress.

One drawback of memory foam is its heat build-up. When it absorbs heat, it becomes warmer. For a sleeper, this can become uncomfortable. Over time, several ways have been used to cool memory foam.

The first solution was to promote air flow to make memory foam breathable. Ventilating the foam by perforation or by cutting channels in its surface allowed air to flow through it and by it.

Then manufacturers began to make the cells in the foam open and more connected to make the foam itself permeable to air. Open-cell memory foam is more breathable than closed cell foam.

Now it is common practice to infuse the memory foam with gel. The gel acts as a heat sink, carrying heat away to where it can dissipate. The most common method of gel infusion is to stir beads of microencapsulated gel into the liquid used to make the memory foam. Variations of this are the size of the beads and the kind of gel. Another method used by a few manufacturers is to swirl liquid gel into the memory foam mixture. This memory foam has streaks of gel. Additionally, a layer of gel itself may be embedded in the layer of memory foam. Some models use this is for lumbar support.

Since memory foam is basically a kind of polyurethane, there may be some emissions. Using more plant-derived oils reduces this. However, memory foam has to be cut more slowly because of its “memory.” And it has to have time to recover before the next cut. This extra time allows the foam to air out more before being put into a mattress then packaged for shipping.

Formerly called “foam rubber,” latex foam is made in a number of ways. Foam rubber was first made by Dunlop, a tire manufacturer. Foaming agents were used to whip liquid synthetic rubber into foam. Then rubber tree sap (natural latex) was whipped and cured into foam. Now there are several kinds of latex foam, depending on the proportion of natural latex and the composition of other ingredients. All natural latex foam is (or should be) made from 100% natural latex sap. Natural latex foam is partly synthetic. Then there is synthetic latex foam. Synthetic ingredients can be petroleum derived or natural ingredients, such as soy oil.

Latex foam is highly resilient. Its recovery time from pressure is virtually instantaneous. Latex is conformable, not as much as memory foam, but it is more durable. Its durability partly depends on the manufacturing process. Latex is used in some mattresses for the support core.

The oldest method is the Dunlop process. Liquid latex is mixed with the foaming agents and poured into molds to cure. The cured latex foam then is cut to specification.

Another common manufacturing method for latex foam is the Talalay process. The liquid latex is fed into a closed mold from which air has been removed. Freezing and insertion of carbon dioxide are used in expanding the foam, and heat is used to cure it. This is a more costly process, but it can be done without toxic ingredients or agents. Also, parts can be molded in their final form.

Like memory foam, latex is sometimes infused with gel for cooling. Latex foam is naturally breathable, and it is cooler than memory foam, but the addition of gel is seen as an added value for cooling and its smoother support. Latex is naturally resistant to bacteria, mold, mildew and dust mites. Properly washed latex foam is hypoallergenic, since allergens have been washed away.

Several mattresses on the market today use several kinds of foams, selected, sized and placed to optimize the use of their characteristics. Gel foams are usually at or near the top of the mattress where cooling is most needed. Firmer, more resilient foams are usually at or near the bottom to provide basic support. Layers in between tailor the comfort level of the mattress as a whole.

This entry was posted on Sunday, February 9th, 2014 at 10:14 PM and is filed under bedrooms, beds, foam, furniture, mattresses . You can follow any responses to this entry through the RSS 2.0 feed. You can leave a response, or trackback from your own site.

Get New Post Notification via Email:

One thought on “Mattress Foams – Part 2”